The history of human footwear is a timeline marked by a single, seismic shift: the Industrial Revolution. Before the mid-19th century, every shoe worn by every person in history was made by hand. Whether it was a Roman sandal, a medieval turnshoe, or a silk slipper for French royalty, a human being cut, stitched, and shaped the materials.

Today, the landscape is vastly different. We live in an era where automated production lines can churn out thousands of pairs of sneakers in the time it takes a master cordwainer to hand-stitch a single welt. Yet, despite the efficiency of modern manufacturing, the allure of the handmade shoe persists. It survives not just as a luxury, but as a testament to anatomical precision and material integrity.

Read Here: How Shoes Are Made

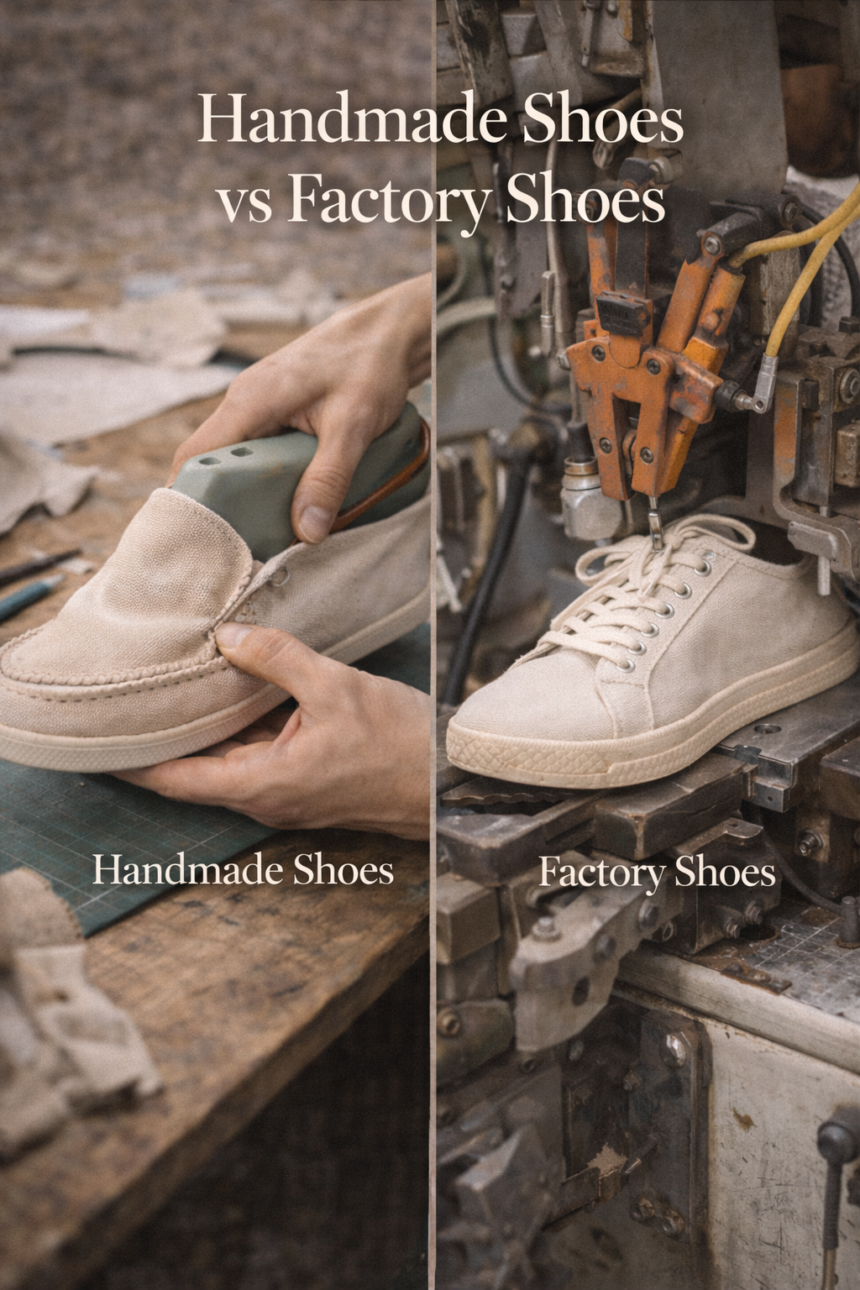

To understand footwear is to understand how it is made. The distinction between handmade and factory-produced shoes is not merely about price or prestige; it is a fundamental difference in philosophy, construction, and longevity. This guide explores the mechanics behind both methods, helping you understand what actually supports your feet.

Two Worlds of Shoemaking

When we discuss the evolution of footwear, we are really discussing the evolution of technology. For thousands of years, the technology was the awl, the hammer, and the knife. The limiting factor was human endurance and skill. The shoemaker was a local essential, much like a blacksmith or a baker.

The introduction of the sewing machine in the 1800s, followed by the lasting machine (invented by Jan Ernst Matzeliger), bifurcated the industry. One path followed the route of efficiency, scalability, and democratization—making shoes accessible to the masses. The other path remained rooted in tradition, focusing on the individual foot and the longevity of the object.

Understanding these two worlds is critical for any consumer. It informs why one pair of boots might last twenty years while another falls apart in six months. It explains why a bespoke oxford feels fundamentally different from a mass-market loafer.

What Are Handmade Shoes?

To define a shoe as “handmade” in the strictest sense (often referred to as bespoke) means that from the initial measurement to the final polish, hand tools were the primary instruments of creation. This is the oldest form of manufacturing, deeply tied to our artisanal heritage.

Traditional Craft Techniques

True handmade shoemaking begins with the “last”—a wooden or plastic mold that mimics the shape of the foot. In factory settings, lasts are standardized. In handmade shoemaking, the last is often carved specifically for the client.

The construction methods used here are revered for their complexity. The most famous is the Hand-Welted construction. A craftsman stitches a strip of leather (the welt) to the upper leather and the insole. This is done blindly, by feel, passing a curved needle through the materials. It creates a waterproof seal and allows the shoe to be resoled multiple times without damaging the upper.

Another technique is Norwegian construction (Norvegese), often used in rugged boots, where the stitching is visible on the exterior, creating a watertight barrier perfect for harsh climates. These techniques require years of apprenticeship to master.

Custom Fit and Personalization

The primary advantage of the handmade process is anatomical accuracy. Human feet are rarely symmetrical; one is often slightly larger or wider than the other. A factory shoe forces the foot to adapt to the shoe. A handmade shoe is built to adapt to the foot.

This personalization extends to aesthetic choices. A client can select the specific hide of leather, the height of the heel, the shape of the toe box, and even the color of the stitching. It is a collaborative process between the wearer and the maker.

Materials and Detail Work

In high-volume production, materials are often chosen for how easily they can be cut by machines. In handmade shoemaking, materials are chosen for character and durability.

A craftsman uses a process called “clicking” to cut leather hides. They inspect the hide for stretch directions and imperfections, cutting the pieces so the shoe will flex naturally with the foot. This level of scrutiny ensures that full-grain leathers are used effectively, developing a rich patina over time rather than cracking.

What Are Factory Shoes?

Factory shoes represent the triumph of modern engineering. They are the reason footwear is affordable and widely available. While “factory-made” can sometimes imply lower quality, it also represents incredible innovation, particularly in athletic footwear and performance gear.

Mass Production Methods

Factory production relies on the assembly line. A shoe is broken down into dozens of individual operations, each performed by a specific worker or robot. One machine cuts the leather (or synthetic mesh), another stitches the upper, and another attaches the sole.

The most common construction method in factory shoes is Cementing. This involves using heavy-duty adhesives to bond the upper to the sole. It is fast, lightweight, and flexible. While traditionalists critique it for being difficult to repair, it is the standard for sneakers and casual shoes because it allows for soft, cushioned soles that stitched construction cannot easily accommodate.

Automation and Technology

Modern factories utilize advanced robotics. Computer Numerical Control (CNC) cutting machines slice fabrics with laser precision, minimizing waste. Automated stitching arms can execute complex patterns in seconds that would take a human minutes or hours.

In the realm of athletic shoes, factories use Injection Molding. Liquid polyurethane or EVA foam is injected into a mold to create soles that offer specific energy return and impact absorption. This level of material science is virtually impossible to replicate in a purely handmade environment.

Consistency and Scalability

The goal of the factory is consistency. A size 9 sneaker bought in Tokyo should fit exactly the same as a size 9 bought in New York. This standardization has allowed global brands to exist. It removes the variables of human error (and human flair), ensuring a predictable product that meets strict quality control standards.

Key Differences Between Handmade and Factory Shoes

When choosing between these two categories, the differences manifest in tangible ways for the wearer.

Comfort and Fit

Factory shoes, particularly those with cemented foam soles, often offer “out-of-the-box” comfort. They are soft and flexible immediately. However, the foam eventually compresses, and the support degrades over time.

Handmade shoes, especially those with leather insoles and cork filling, often require a “break-in” period. Initially, they may feel stiff. Over weeks of wear, the heat and pressure of the foot mold the cork and leather to the specific contours of the wearer’s foot. The result is a custom orthotic bed that provides superior long-term support, even if the initial comfort wasn’t instantaneous.

Durability and Construction

Durability is the hallmark of the handmade shoe. Because mechanical stitching (like the Goodyear welt or Blake stitch) connects the components, a cobbler can cut the stitches, remove a worn-out sole, and sew on a new one. A well-maintained pair of handmade boots can last 10, 20, or even 30 years.

Factory shoes using cement construction are often disposable. Once the glue fails or the sole wears down, repairing them is often more expensive than replacing them. They are designed for a finite lifecycle.

Design Flexibility

Factory production excels at complex, multi-material designs—think of a basketball shoe with mesh, plastic cages, and air bubbles. These require industrial bonding and molding.

Handmade production excels at structured, classic elegance. The limitations of hand-stitching mean the designs often lean toward timeless silhouettes—oxfords, derbies, loafers, and boots—where the beauty comes from the material and the line of the stitching.

Cost and Accessibility

Handmade shoes are an investment. You are paying for skilled labor, premium materials, and time. Prices often start in the hundreds and can reach the thousands. Factory shoes benefit from economies of scale, making them accessible to a global audience at a fraction of the cost.

Read Here: Casual Shoes vs Formal Shoes

How Manufacturing Influences Shoe Silhouettes

The method of production dictates the shape of the final object. This is an often-overlooked aspect of fashion history.

Structured Handmade Shapes

Handmade shoes are defined by the “waist”—the middle part of the shoe under the arch. A skilled maker can create a “beveled waist,” where the sole is shaved down and tucked tight against the leather upper. This creates a sleek, hourglass curve that looks elegant and supports the arch. The silhouette is sharp, sculpted, and organic.

Modern Industrial Designs

Factory shoes often have blockier, flatter silhouettes. Machines have difficulty maneuvering around tight curves like a human hand can. Consequently, factory lasts are often wider and flatter to accommodate the machinery and a broader range of foot shapes. This has influenced the modern aesthetic, leading to the chunky, substantial profiles seen in streetwear and contemporary fashion.

Cultural and Psychological Meaning of Handmade vs Factory Shoes

The shoes we wear signal our values and our place in society. This has been true since the invention of footwear.

Handmade Shoes as Luxury Identity

In a world of mass production, the handmade object has become a symbol of status and “slow fashion.” Wearing bespoke shoes signals an appreciation for heritage and sustainability. It rejects the culture of disposability. Psychologically, there is a connection between the wearer and the maker—a sense that the object has a “soul” because it bears the mark of human effort.

Factory Shoes as Modern Lifestyle Tools

Factory shoes represent utility and modernity. They are the tools of the athlete, the commuter, and the worker. They signify a connection to current trends and technology. A pair of high-tech sneakers represents the cutting edge of material science. They are democratic objects—a billionaire and a student might wear the exact same pair of factory-produced sneakers.

Which Option Is Better for Different Lifestyles?

The “better” shoe depends entirely on the application.

Everyday Wear and Commuting

For those walking long distances on concrete or standing all day, high-quality factory shoes with advanced cushioning (sneakers or hybrids) are often superior. The shock absorption provided by modern foams is hard to beat for pure utility.

Formal Occasions and Professional Settings

For business, weddings, or formal events, the handmade shoe reigns supreme. The aesthetic of a hand-polished leather sole and the clean lines of a hand-lasted upper provide an elegance that molded rubber cannot replicate. Furthermore, for the professional who wears a suit daily, the long-term comfort of a broken-in leather shoe is unmatched.

Collectors and Enthusiasts

Collectors exist in both worlds. The “sneakerhead” collects rare factory productions, valuing the design, the collaboration, and the scarcity created by marketing. The classic shoe enthusiast collects handmade footwear, valuing the patina, the construction method, and the specific tannery from which the leather originated.

The Future of Handmade and Factory Shoemaking

We are approaching a convergence point where these two worlds meet.

AI-Assisted Craftsmanship

We are seeing the rise of “digital bespoke.” Startups are using AI and smartphone scanning technology to create 3D models of a customer’s foot. These measurements are sent to a factory where automated machines cut the leather to the exact custom specification. This brings the custom fit of the handmade world to the scalability of the factory.

Sustainable Manufacturing

As environmental concerns grow, the “repairability” of handmade shoes is becoming a model for the future. Factories are exploring ways to make sneakers circular—using glues that can be dissolved to separate materials for recycling, or designing modular shoes that can be repaired like traditional boots.

Hybrid Production Models

The future will likely see more hybrids: shoes with 3D-printed soles (factory precision) attached to hand-stitched uppers (artisanal quality). This blends the ergonomic benefits of modern science with the durability and beauty of traditional craft.

Read Here: The Psychology of Sneaker Culture and Modern Identity

Conclusion: Craftsmanship Meets Modern Innovation

The divide between handmade and factory shoes is not a battle of good versus bad. It is a spectrum of choice. The handmade shoe reminds us of our history, offering a connection to the earth and the artisan, built to last a lifetime. The factory shoe propels us into the future, offering performance, accessibility, and the wonders of synthetic engineering.

For the true footwear enthusiast, there is room in the closet for both. One for the journey that requires speed and cushioning, and one for the path that requires structure, elegance, and the timeless tap of a leather heel on the pavement.

Leave a Reply