When you hold a shoe in your hand, your eyes likely land on the material first—the sheen of the leather or the texture of the suede. Then, you might notice the silhouette, the shape of the toe, or the height of the heel. But if you look closer, past the surface-level aesthetics, you will find the true storyteller of the shoe’s quality and history: the stitching.

Stitching is the unsung hero of footwear. It is the literal thread that binds disparate pieces of material into a functional, three-dimensional object capable of protecting the human foot. In the world of horology, enthusiasts obsess over the movement inside a watch case. In footwear, the equivalent obsession is the construction method—the specific way the upper is stitched to the sole.

Read Here: Glue vs Stitch Construction

Understanding shoe stitching is not just an academic exercise for designers; it is a crucial skill for anyone who wishes to invest in quality footwear. The stitching technique dictates how a shoe moves, how long it lasts, whether it can be repaired, and how it handles the elements. From the historic robustness of the Goodyear welt to the flexible innovation of Strobel stitching, every stitch tells a story of engineering and artistry.

Why Stitching Matters in Shoemaking

At its core, a shoe is a feat of engineering. It must bear the entire weight of the human body, endure thousands of steps per day, and resist friction, moisture, and impact. Glue and cement have their place in modern manufacturing, but stitching remains the gold standard for durability and structural integrity.

Structural Integrity vs. Aesthetic Detail

In footwear design, stitching serves two distinct purposes: structural and decorative. Structural stitching is the skeleton of the shoe. It joins the quarter to the vamp, the upper to the lining, and most importantly, the entire upper assembly to the sole unit. If these stitches fail, the shoe falls apart.

Decorative stitching, on the other hand, is about visual language. Think of the intricate embroidery on a cowboy boot or the brogueing on a wingtip Oxford. While these stitches don’t always hold the shoe together, they carry the cultural and historical lineage of the footwear. However, the most critical stitching lies hidden beneath the insole or visible only at the welt—the point where engineering meets craftsmanship.

The Historical Significance of the Stitch

Historically, shoemaking was a laborious hand-craft. A cobbler would spend days punching holes with an awl and pulling waxed linen threads through thick leather hides. The industrial revolution changed this with the invention of the sewing machine, specifically the McKay (Blake) and Goodyear machines in the 19th century. These inventions didn’t just speed up production; they democratized quality footwear. Suddenly, durable, stitched shoes were accessible to the masses, not just the aristocracy.

Understanding these techniques connects us to a lineage of makers who solved complex problems of physics and anatomy with nothing more than needle and thread.

Basic Shoe Stitching Concepts

Before diving into complex welting methods, it is essential to understand the foundational elements of shoe stitching. The quality of a stitch is determined by tension, material, and the method of interlocking.

Upper Stitching vs. Sole Stitching

Shoe construction is generally divided into two phases: “closing” the upper and “bottoming” the shoe.

- Upper Stitching (Closing): This involves sewing together the various pieces of leather or fabric that make up the top part of the shoe. This requires precision and delicacy. The stitches here must be flush against the foot to prevent irritation (blisters) while being strong enough to withstand the flexing of the foot during walking.

- Sole Stitching (Bottoming): This is the heavy lifting. This stitching attaches the finished upper to the midsole and outsole. This requires heavy-duty machinery or significant hand strength, as the needle must penetrate multiple layers of thick leather, rubber, or cork.

Thread Materials and Strength

The thread itself is a critical component. In high-end bespoke shoemaking, natural fibers like linen or cotton are often used, treated with beeswax or pitch to waterproof them and prevent rotting. The wax also helps the thread “bite” into the leather, creating a seal that holds even if the thread snaps elsewhere.

In modern mass production, bonded nylon or polyester threads are the standard. These synthetics offer incredible tensile strength and resistance to rot, though they lack the traditional aesthetic and organic movement of natural fibers. The choice of thread gauge (thickness) also plays a role; a chunky contrast stitch on a boot conveys ruggedness, while a fine, high-count stitch on a dress shoe signals elegance.

Hand Stitching vs. Machine Stitching

The debate between hand and machine stitching is central to luxury footwear. A machine uses a “lockstitch,” where two threads (top and bobbin) loop around each other. If one breaks, the whole row can unravel.

Hand stitching, specifically the “saddle stitch” used in bespoke shoemaking, uses two needles on a single thread passing through the same hole in opposite directions. This creates a knot at every single stitch. If a saddle stitch breaks, the rest of the seam remains intact. This level of durability is why bespoke shoes can cost thousands of dollars—you are paying for the time it takes to create a bond that machinery cannot replicate.

Read Here: How Shoes Are Made

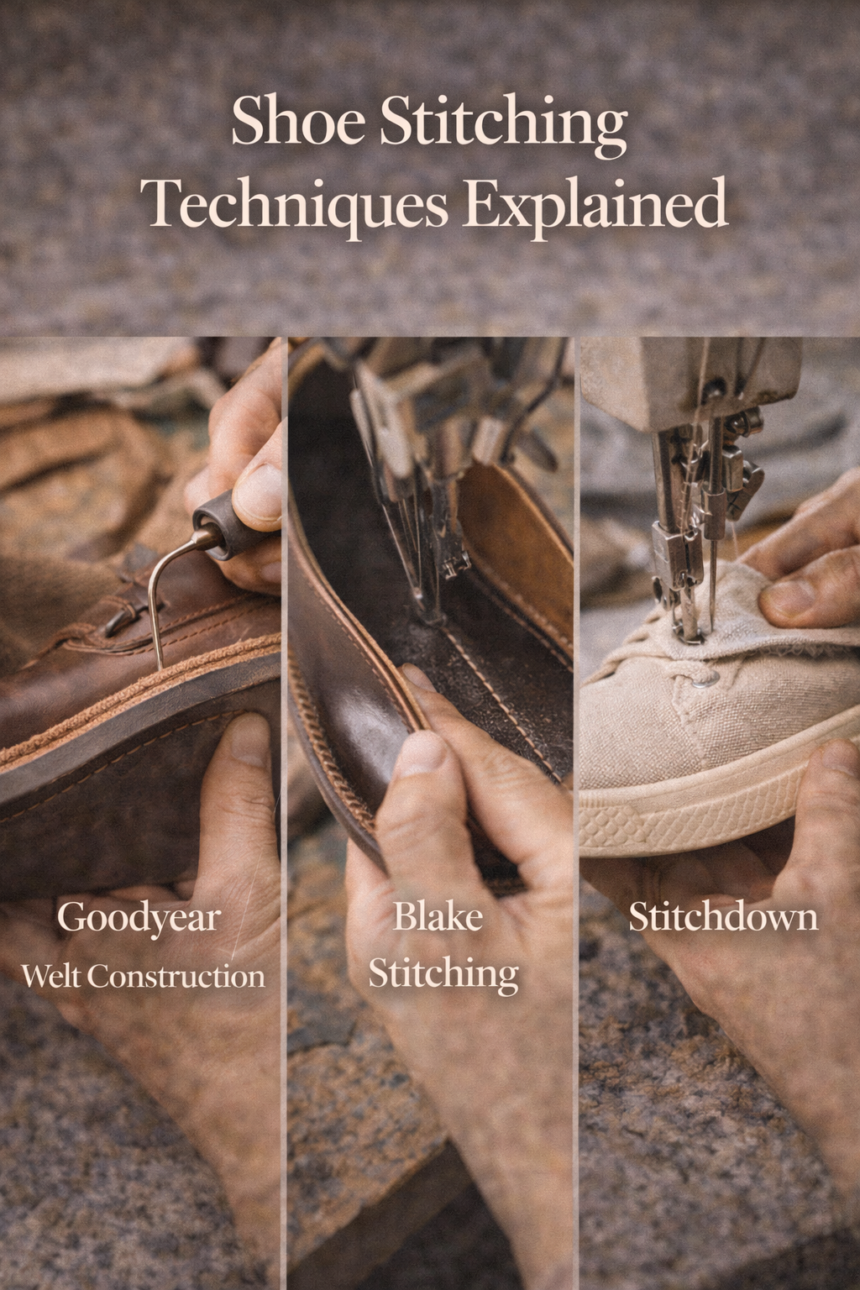

Common Shoe Stitching Techniques

The method used to attach the sole to the upper defines the shoe’s category, price point, and lifespan. Here are the four titans of shoe construction.

1. Blake Stitch Construction

Named after Lyman Reed Blake, who invented the machine in 1858, this method is a staple of Italian shoemaking.

The Technique: The upper is wrapped around the insole and attached between it and the outsole. A single stitch runs from inside the shoe, through the insole, the upper, and the outsole. If you look inside a Blake-stitched shoe, you can often see the row of stitching running around the perimeter of the footbed.

The Result: Because there are no intermediate layers (like a welt), Blake-stitched shoes are incredibly flexible and sleek. They require less break-in time than heavier constructions. They allow for a close-cut sole, giving the shoe a refined, elegant silhouette popular in dress loafers.

The Drawback: Because the stitch goes through to the inside of the shoe, moisture can wick up from the ground into the footbed. They are harder for a cobbler to resole than Goodyear welted shoes, though not impossible.

2. Goodyear Welt Construction

This is the tank of shoe construction, developed by Charles Goodyear Jr. in 1869. It is the hallmark of British and American heritage footwear.

The Technique: This method uses an intermediary strip of leather, rubber, or plastic called a “welt.” The welt is stitched to the upper and the insole rib (a canvas ridge glued to the insole). Then, a separate stitch attaches the welt to the outsole. Crucially, the stitch that holds the shoe together does not penetrate the interior of the shoe. The gap between the insole and outsole is filled with cork.

The Result: Goodyear welted shoes are virtually waterproof and incredibly durable. The cork filling molds to the wearer’s foot over time, creating a custom footbed. Most importantly, because the outsole is stitched to the welt rather than the upper, a cobbler can easily cut off the old sole and stitch on a new one without damaging the leather upper.

The Drawback: These shoes are stiff, heavy, and expensive to manufacture. They often require a painful “break-in” period before they become comfortable.

3. Strobel Stitching

If you are wearing sneakers right now, they are likely Strobel stitched. This technique prioritized comfort and flexibility above all else.

The Technique: The upper material is sewn to a fabric “sock” or bottom board using a specific machine that creates a loop stitch (similar to a serger used in clothing). This creates a flexible sock-like pouch that is then cemented (glued) to the midsole and outsole.

The Result: A shoe that is lightweight, incredibly flexible, and moves naturally with the foot. It is the standard for athletic footwear, running shoes, and casual slip-ons.

The Drawback: Strobel shoes cannot be resoled. Once the sole wears out or the cement fails, the shoe is generally discarded. They lack the structure and support of welted footwear.

4. Cemented Construction (The “Bonded” Method)

While not technically a “stitching” technique, it is the most common method of shoe construction today and defines the baseline against which stitched shoes are measured.

The Technique: The upper is roughened and glued directly to the sole using heavy-duty adhesives. There are no structural stitches holding the bottom to the top.

The Result: Cheap, fast, and easy to mass-produce. It allows for sleek silhouettes and lightweight shoes.

The Drawback: Durability is low. When the glue dries out or fails (delamination), the sole simply peels off. These shoes generally cannot be repaired.

How Stitching Influences Shoe Silhouettes

Stitching is not just about holding a shoe together; it dictates the visual volume and “weight” of the footwear. The construction method acts as a skeleton that defines the outer shape.

Structured Formal Shoes

A Goodyear welt adds a visible rim (the welt) around the edge of the shoe. This extends the footprint slightly beyond the upper, creating a wider, more grounded silhouette. This is why a sturdy brogue or a combat boot looks substantial—the stitching adds physical width. This structure commands authority, making it ideal for business, formal, or workwear environments.

Flexible Athletic Designs

Strobel stitching allows the upper to tuck under the foot, disappearing directly into the midsole foam. This allows for a streamlined, aerodynamic look. In athletic design, the stitching is often internal or minimal to reduce drag and weight. The silhouette mimics the anatomy of the foot itself, rather than building a platform underneath it.

Minimalist vs. Chunky Construction

The visible stitch is a design element. Dr. Martens, for example, built an entire brand identity around a single yellow Z-welt stitch. That contrast stitch makes the shoe look chunkier, rebellious, and industrial. Conversely, a “wholecut” Oxford might use hidden stitching or very fine blind stitching to make the shoe appear as a single, seamless piece of leather, emphasizing fluidity and minimalism.

Stitching Techniques in Different Shoe Types

Different functional requirements demand different stitching solutions. A marathon runner has different needs than a construction worker or a corporate lawyer.

Sneakers: The Domain of the Strobel

Sneakers require multi-directional flexibility. A runner needs the toe to bend 45 degrees with every step. Strobel stitching allows the upper and midsole to act as a single, cohesive unit that distorts and recovers instantly. Modern innovations have introduced “knit” uppers where the stitching is actually the fabric itself, woven by computer-controlled looms to vary tension and breathability without any seams at all.

Boots: The Fortress of the Stitch Stitchdown

Work boots and hiking boots often utilize “Stitchdown” or “Norwegian Welt” construction. In Stitchdown (Veldtschoen), the upper leather is flared outwards and stitched directly to the midsole. This creates a shingle-like effect that sheds water away from the shoe, rather than allowing it to pool in the crevice of a welt. It creates a wide, stable base ideal for uneven terrain.

Loafers: The Moccasin Construction

True moccasins and many loafers utilize a unique hand-stitching technique. The leather wraps under the foot (forming the sole and sides) and is stitched to a U-shaped piece on top (the apron) using a “pucker” stitch. This is why loafers feel like slippers—because, structurally, the leather cradles the foot like a hammock. The stitching here must be loose enough to allow movement but tight enough to hold shape.

Craftsmanship vs. Automation in Modern Stitching

We are currently in a fascinating era where hyper-traditional techniques exist alongside space-age automation.

Traditional Handmade Techniques

There is a resurgence in the appreciation for “hand-welted” shoes. In small workshops in Northampton, Florence, and Tokyo, cordwainers still sew welts by hand. This is not just nostalgia; a hand-welted shoe allows for a tighter waist (the middle part of the shoe) and a more sculpted fit than a Goodyear machine can achieve. It represents the pinnacle of human dexterity.

Industrial Stitching Technology

Conversely, brands like Nike and Adidas employ automated stitching arms that move with sub-millimeter precision. These machines can execute complex embroidery patterns for structural support (like Nike’s Flywire) that a human hand could never replicate consistent. This is “stitching as engineering,” where the direction and density of the thread are calculated to manage distinct physical forces.

Quality Control Processes

The mark of quality in stitching is consistency. In mass production, optical sensors monitor stitch length and thread tension. In handmade shoes, the “fudging wheel” is used to mark stitch intervals, but the human eye is the final judge. A skipped stitch in a factory shoe is a defect; a slight variation in a handmade shoe is a signature of its maker.

Read Here: Handmade Shoes vs Factory Shoes

The Future of Shoe Stitching Technology

As we look toward the future of footwear, the very concept of “stitching” is being challenged and reinvented.

Laser Stitching and Bonding

We are seeing the rise of “no-sew” overlays, where thermoplastic polyurethanes (TPU) are fused to mesh using heat and pressure. This eliminates the weight of the thread and the needle holes that can act as tear points. However, high-end fashion is experimenting with laser-etched “stitching” that mimics the look of a seam without the physical thread, purely for aesthetic heritage.

Sustainable Construction Methods

The biggest problem with cemented shoes is that they are hard to recycle—you can’t easily separate the rubber from the leather. New stitching technologies aim to make disassembly easier. Brands are experimenting with water-soluble threads or mechanical locking stitches that can be unraveled at the end of the shoe’s life, allowing the materials to be sorted and recycled.

AI-Assisted Manufacturing

AI is beginning to optimize stitching patterns to reduce material waste. By analyzing the stress points on a shoe design, AI can tell a manufacturer exactly where reinforcement stitches are needed and where they can be removed, creating a shoe that is lighter, stronger, and uses less thread.

Stitching as the Backbone of Shoe Construction

It is easy to be seduced by the silhouette of a stiletto or the colorway of a limited-edition sneaker. But the soul of the shoe lies in the stitch. It is the connection point between the ancient history of human protection and the modern future of fashion technology.

Whether it is the waterproof utility of a Goodyear welt, the sleek flexibility of a Blake stitch, or the seamless innovation of a knit upper, the technique used to bind your footwear dictates your experience of the world. To understand stitching is to understand quality. It allows you to look at a price tag and know exactly what you are paying for—not just a brand name, but a specific lineage of engineering and craftsmanship.

Next time you tie your laces, take a moment to look at the welt, the seams, and the joins. You aren’t just looking at thread; you are looking at the result of thousands of years of human ingenuity, stitched together one loop at a time.

Leave a Reply