When you slip your foot into a high-quality Oxford or a sleek Derby, the sensation is immediately distinct from the cushioned hug of a sneaker. There is a rigidity, a weight, and a defined architecture that feels almost architectural. This isn’t accidental. The construction of formal footwear is a discipline rooted in centuries of tradition, prioritizing silhouette, durability, and a specific aesthetic language over the soft, unstructured comfort of modern athletic wear.

To understand formal shoes is to understand a different philosophy of movement. While a running shoe is designed to absorb impact and propel the body forward using synthetic foams and knits, a formal shoe is built to support the foot through structure. It is a vessel crafted from organic materials—primarily leather—that requires a break-in period because it is designed to mold to the wearer over time, rather than accommodating them instantly.

This guide explores the anatomy of formal footwear, dissecting the structural decisions, material choices, and craftsmanship techniques that separate a dress shoe from every other item in your closet. From the hidden cork filling to the precise stitching of the welt, we will uncover why formal shoes look, feel, and age the way they do.

See also Casual Shoes vs Formal Shoes

What Makes Formal Shoes Unique?

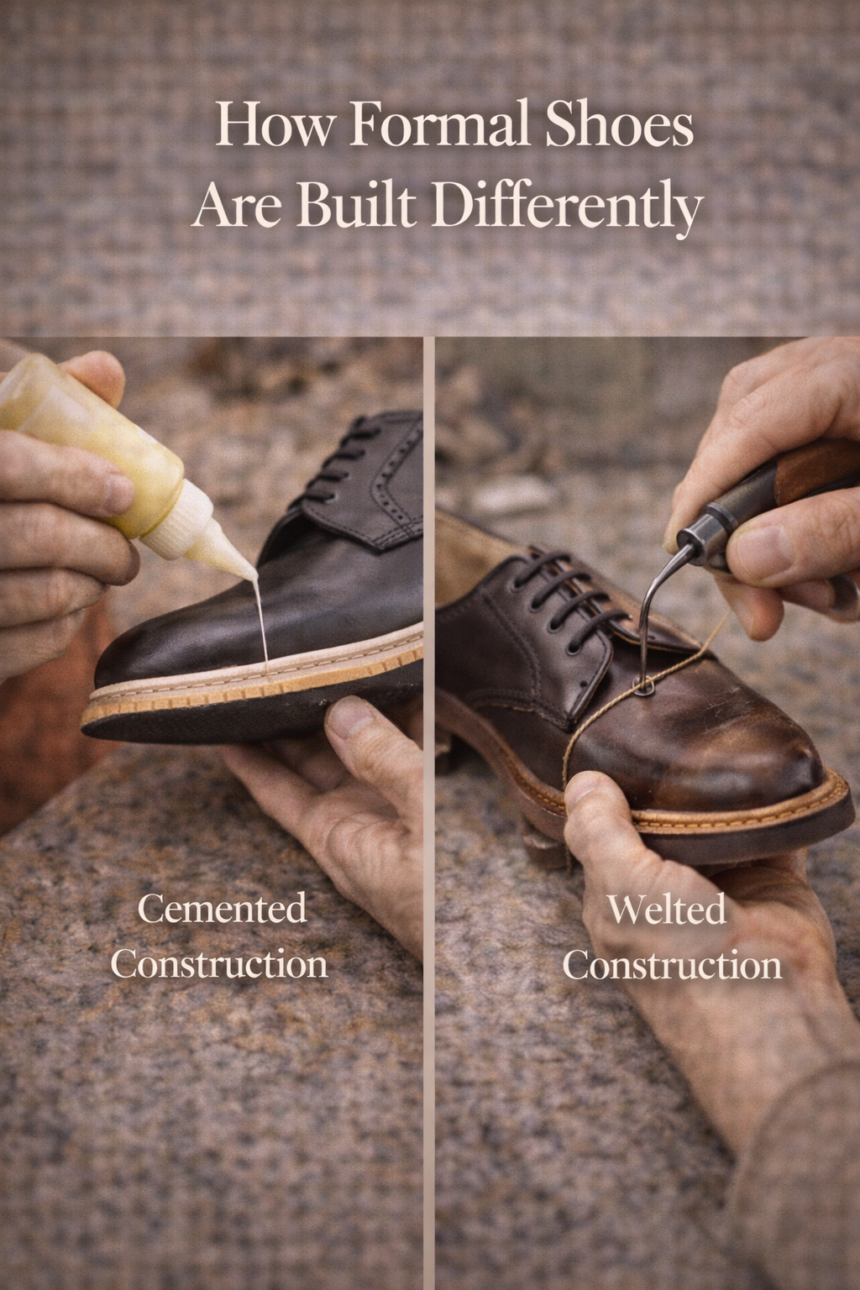

The fundamental difference between formal and casual footwear lies in the relationship between the upper and the sole. In the world of sneakers (cemented construction), the upper is glued to a soft midsole. In traditional formal footwear, the upper is mechanically fastened—stitched—to the sole through a series of complex layers. This creates a shoe that is heavier and stiffer, but also one that is serviceable.

Formal shoes are defined by their profile. The “last”—the three-dimensional mold upon which the shoe is constructed—dictates a shape that often tapers at the toe and hugs the arch. Unlike the broad, flat footprint of a sneaker designed for stability during erratic movement, a dress shoe is designed for a controlled gait. The heel provides a distinct elevation, changing the wearer’s posture, forcing the spine straighter and the stride to become more deliberate.

Furthermore, aesthetics in formal footwear are reductive. The goal is often to hide the engineering. Seams are skived (thinned) to lay flat; stitching is kept neat and sometimes hidden in channels; and the transition from heel to sole is sanded to a seamless curve. This contrasts sharply with technical footwear, where the technology (air bubbles, gel pads, stabilizers) is often exposed as a design feature.

Materials Used in Formal Shoe Construction

The soul of a dress shoe is, quite literally, its skin. While modern manufacturing has introduced synthetics, the hierarchy of formal footwear remains strictly bound to leather quality. The structural integrity of the shoe depends on it.

Full-Grain and Top-Grain Leather

The vast majority of high-end formal shoes are constructed from calfskin. Specifically, full-grain leather is the gold standard. This is the top layer of the hide, including the grain, which has not been sanded or buffed to remove imperfections. Its fibers are dense and tightly packed, providing exceptional durability and water resistance. Crucially, full-grain leather breathes and absorbs shoe polish, allowing it to develop a “patina”—a unique sheen and depth of color that improves with age.

Top-grain leather is the second tier. It has had the very top layer sanded off to remove blemishes, then a fake grain is stamped onto it. While smoother initially, it lacks the longevity of full-grain and utilizes a plastic coating that prevents the leather from breathing or absorbing polish as effectively.

Structured Linings

Slice a dress shoe in half, and you will find it is not a single layer of leather. The “upper” is backed by a lining, usually made of a softer, vegetable-tanned leather. Between these layers, stiffeners are inserted at the toe (the toe puff) and the heel (the counter).

In sneakers, these stiffeners might be plastic or foam. In traditional shoemaking, they are often made of leather or treated canvas soaked in paste. These hidden components are what keep a dress shoe from collapsing. They ensure the toe box retains its crisp shape even after years of wear, and they lock the heel in place to prevent slipping.

Traditional Soles

The sole of a formal shoe is a stack of compressed leather. This material choice is vital for the shoe’s “click” sound and its breathability. Leather soles are stiff when new but flex where the foot bends over time. However, they offer zero shock absorption compared to rubber. To mitigate this, high-quality constructions often include a layer of cork spread between the insole and the outsole. This cork layer molds to the wearer’s footprint, creating a custom footbed that offers a personalized fit no foam insole can replicate.

Stitching Techniques in Formal Shoes

How the upper is attached to the sole is the single most important factor in a formal shoe’s lifespan and price point. This mechanical bond defines the shoe’s water resistance and whether it can be resoled.

Goodyear Welt Construction

Considered the benchmark for British and American shoemaking, the Goodyear Welt is a labor-intensive method. A strip of leather (the welt) is stitched to the upper and the insole. Then, a separate stitch attaches the welt to the outsole.

The magic of this construction is that the stitches do not run directly from the outside of the sole to the inside of the shoe. This creates a highly water-resistant barrier. Furthermore, because the outsole is stitched to the welt rather than the upper, a cobbler can easily cut the old sole off and stitch a new one on without damaging the leather upper. A Goodyear-welted shoe, properly cared for, can last 20 years or more.

Blake Stitch Method

Popular in Italian shoemaking, the Blake stitch is simpler and sleeker. The upper is wrapped around the insole, and a single row of stitching goes straight through the insole, the upper, and the outsole.

Because there is no welt, the shoe can be made much lighter and more flexible. The sole can be cut closer to the edge of the upper, resulting in a slimmer, more elegant profile. The trade-off is water resistance (water can wick up through the stitches) and durability. While Blake shoes can be resoled, it requires a specific machine, and doing it too many times can perforate the uppers.

Hand-Finished Details

At the highest tier of shoemaking (bespoke), machine stitching is replaced by hand stitching. A craftsman uses a curved awl and waxed threads (often tipped with boar bristles) to create a “lock stitch.” This is stronger than a machine stitch because if one loop breaks, the whole seam doesn’t unravel. You will often see this in the “waist” of the shoe—the narrow part under the arch—which can be beveled much tighter by hand than by any machine.

The Lasting Process and Structured Fit

The “last” is the wooden or plastic form that mimics the human foot. “Lasting” is the process of pulling the leather upper over this form to give the shoe its shape. In formal footwear, this process is aggressive. The leather must be stretched tight to remove wrinkles and ensure it mirrors the contours of the last perfectly.

Board Lasting for Stability

Unlike running shoes, which are often “slip-lasted” (sewn into a sock shape and then glued), formal shoes are “board-lasted.” The insole is tacked to the bottom of the last, and the upper is pulled over and secured to it. This creates a rigid backbone for the shoe. It provides a stable platform that supports the foot structure, reducing fatigue during long periods of standing, despite the lack of cushioning.

Toe Shape and Proportion

The toe shape is the most defining characteristic of a formal silhouette. Whether it is a chisel toe, a rounded almond toe, or a sleek point, the shape is achieved by the internal structure (the toe puff) mentioned earlier. In manufacturing, the shoe is left on the last for a period of time (from a few hours in mass production to weeks in bespoke) to allow the leather to “memorize” this shape. This is why a cheap dress shoe looks undefined and blob-like after a month, while a quality one retains its sharp lines.

Heel Construction

The heel of a dress shoe is built in layers, known as “lifts.” In quality footwear, these are stacked pieces of leather, glued and nailed together. The final layer is usually a combination of leather and a rubber “dovetail” piece for traction. This stacked construction absorbs some shock, but its primary purpose is stability and elevation. The pitch of the heel must be perfectly calculated; if it is too high or low relative to the toe spring, it will throw off the wearer’s balance.

See also Lasting Process in Shoemaking

How Formal Shoe Soles Differ From Sneakers

The undercarriage of a formal shoe is a study in minimalism. Where a sneaker uses volume—thick EVA foam, visible air units, chunky treads—to provide comfort, the formal shoe uses density.

Leather Outsoles

A leather outsole is essentially a hard skin. It provides very little traction on slick surfaces until it has been scuffed up. However, its sleekness is essential for the formal aesthetic. It allows the foot to slide slightly, which is desirable in dancing or when pivoting in a suit. Visually, a leather sole maintains the clean lines of the shoe, disappearing under the upper rather than protruding like the sole of a chunky sneaker.

Thin Cushioning Layers

Between the insole and outsole, there is often a steel or wooden “shank.” This is a rigid strip that sits under the arch. It prevents the shoe from bending in the wrong place. A shoe should flex at the ball of the foot, not the arch. This shank provides structural support that a foam midsole cannot. While it feels hard, it prevents the foot from collapsing and straining the plantar fascia.

Elegant Profiles

The “waist” of the sole—the area between the heel and the ball of the foot—is often shaved down to be as narrow as possible in formal shoes. This is purely aesthetic, creating a violin-like curve that mimics the arch of the foot. It lightens the visual weight of the shoe, making it look refined and agile.

Formal Shoe Silhouettes and Design Language

The construction methods allow for specific styles that have become codified in the lexicon of menswear.

Oxfords and Derbies

The distinction here is constructional. In an Oxford (or Balmoral), the shoelace eyelet tabs are stitched under the vamp (the front section of the shoe). This is “closed lacing.” It creates a smooth, unbroken line that looks cleaner and more formal.

In a Derby (or Blucher), the eyelet tabs are stitched on top of the vamp. This is “open lacing.” It allows the shoe to open wider, accommodating higher arches, but the visible flaps make it inherently more casual and rugged.

Loafers and Monk Straps

These slip-on styles rely entirely on the lasting process for fit. Without laces to tighten the shoe, the “throat” of the shoe must be shaped perfectly to grip the foot. This requires precise cutting of the leather pattern. A Monk Strap replaces laces with a buckle and strap, adding a piece of hardware that acts as a focal point, requiring reinforced stitching where the stress of the strap pulls against the leather.

Pointed vs Rounded Toe Shapes

The geometry of the toe box dictates the formality. A longer, sleeker toe elongates the leg line and looks elegant under dress trousers. A rounder, bulbous toe is associated with workwear or country boots. The construction of a sleek toe requires thinner, higher-quality leather that can be pulled tightly over a sharp last without tearing.

Handmade Craftsmanship vs Modern Production

The industrial revolution changed shoemaking, but the best formal shoes still rely on human hands.

Traditional Shoemaking Techniques

In bespoke or high-end bench-grade shoemaking, the leather is cut by hand (clicking) to ensure the best part of the hide is used for the most visible parts of the shoe. The lasting is done by hand, using pliers to pull the leather until the tension is perfect. This manual tensioning allows the maker to adjust for the specific stretchiness of that particular piece of hide—something a machine cannot feel.

Industrial Production Differences

In mass production, lasers cut the leather, and hydraulic machines pull the uppers over the lasts in seconds. While efficient, this creates a generic fit. The internal components are often plastic or cardboard rather than leather. These shoes may look “formal” on the shelf, but they lack the structural integrity to maintain that formality after wear. They crease incorrectly, the soles separate, and the heels collapse.

See also Handmade Shoes vs Factory Shoes

Why Formal Shoes Feel Different to Wear

The “uncomfortable” reputation of dress shoes is often a misunderstanding of their mechanics.

Structured Support

A well-made formal shoe offers orthopedic support through rigidity. The shank supports the arch, and the tight heel counter creates a locked-in feeling. Once the cork footbed molds to the foot, the pressure is distributed evenly across the sole.

Material Stiffness

The stiffness is a feature, not a bug. It protects the foot and communicates a sense of purpose. However, this requires a break-in period. The fibers of the leather must relax at the flex points. A sneaker feels good immediately but degrades immediately; a dress shoe feels stiff immediately but improves indefinitely.

Cultural Expectations

The construction also enforces a cultural standard. The click of the heel, the shine of the leather, and the upright posture the shoe encourages are all signals of professionalism and attention to detail. The shoe is built to project an image of stability and tradition.

The Future of Formal Shoe Construction

Even this bastion of tradition is evolving. The modern workplace is casualizing, and footwear is adapting.

Hybrid Formal Sneakers

We are seeing the rise of “dress sneakers”—uppers that look like Oxfords or Derbies but are lasted onto rubber cup-soles or EVA foam units. This attempts to marry the aesthetic of the formal upper with the biomechanics of the sneaker.

Sustainable Leather Alternatives

As scrutiny on the leather industry grows, shoemakers are experimenting with mushroom leathers (mycelium) and cactus leathers. The challenge is structural: can these materials handle the intense tension of the lasting process and the wear-and-tear of a Goodyear welt?

Lightweight Structured Designs

New technology is allowing for traditional looks with lighter weights. Micro-cellular rubber soles can mimic the look of leather stacks but weigh half as much. Hollowed-out heels and flexible insoles are being integrated into traditional Goodyear welts to reduce the break-in time without sacrificing the repairability.

Conclusion: Craftsmanship Defines Formal Footwear

A formal shoe is more than a covering for the foot; it is a feat of structural engineering designed to bridge the gap between the organic human form and the rigid demands of social geometry. From the density of the heel stack to the hidden layer of cork, every element serves a purpose.

While sneakers are disposable tools for comfort, formal shoes are permanent investments in style. They are built differently because they are meant to be worn differently—with intention, with care, and with an appreciation for the centuries of craftsmanship stitched into every welt.

Leave a Reply